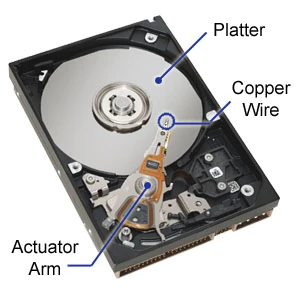

You can rewire the motor with larger gauge wire and attach blades to it and use it as a generator. Hard drive spindle motor is a brushless motor with wye wiring with 4 connectors.

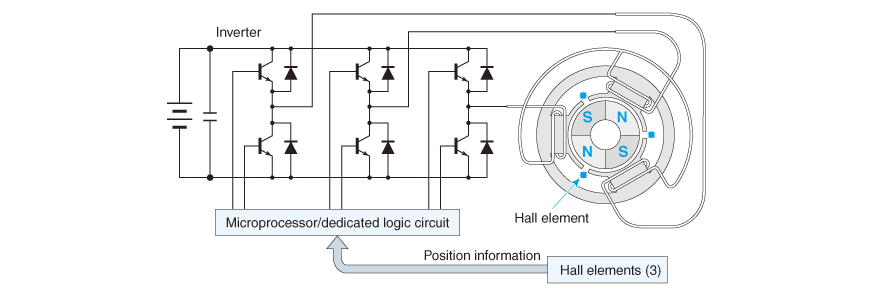

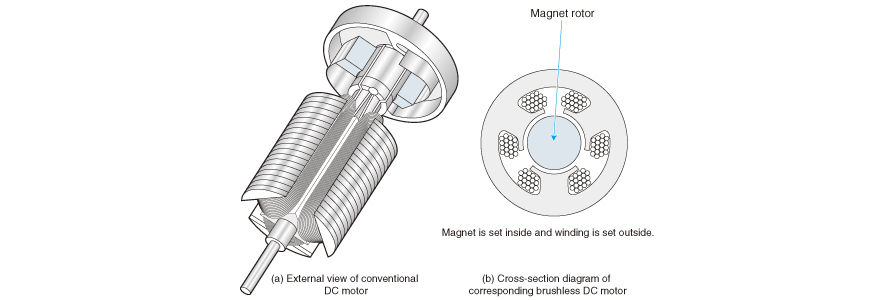

2 2 2 Structure And Application Of Brushless Dc Motors

Hard disk drive motor 3 wire connection diagram. The core of vcm controller can withstand working temperature of 100c212f. The motor maximum speed is 4500 rpm 75 rotationsecond and the maximum power is reached during the seeki n g phase is about 64w. Find the common then attach the other three to the speed. Begingroup you cant easily control the hdd motor via ide cable. You could even use it as a generator straight out of the hard drive but it will not supply that much current or voltage. Is there a very simple guide to drive this 4 wire motor of mine.

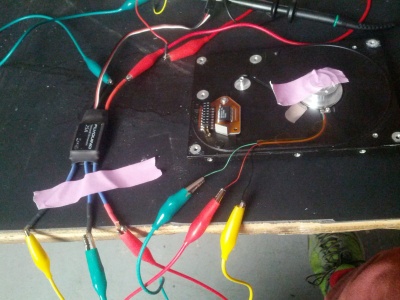

Here are the photos of my motor. The hard drive is mounted so the end with the connections faces inside the computer. The pre wired board looks like this. Ive seen many websites discussing about dvdcdrom motor but most of them are 11123 wires. Before we going to start this first you need to know about the hard disc mototor and how its working. For various reasons i want to run a hdd motor without spending a fortune on electronics i dont really understand so this is how i did it.

When you apply power to a drive mcu chip reads content of the flash chip into memory and starts the code. The chinese 5v 12v bldc motor driver board for hard drive motor 34 wire. Endgroup andrejako apr 19 13 at 1503. Blcd motor control circuit in this article i would like to share a very informative topic and circuit diagram for your salvaged hard disc drive spindle motormost electronic hobbyist thinks that such hard disc drives spindle motors are good only in very specific situations. Flash chip stores part of the drives firmware. I will be using it to be the motor of my arduino rotating led matrix display otherwise known as pov.

Now to the lazy mans slapdash jump. The driver board can be used to drive both 3 wire and 4 wire three phase brushless dc motors. It controls spindle motor rotation and heads movements. Without such code drive wouldnt even spin up. Running a hard drive motor with an rc speed controller. The sides of the hard drive have pre drilled threaded holes for easy mounting in the 35 inch drive bay in the computer case.

Mine is 4 wires. In this projet i re use a bldc motor that i retrieved from an old hdd the seagate st31722aits a 35 inch hdd and 17gb of storage capacity. The same ideas can be used to rewire a 3 phase motor to. Besides it does have some nifty options like motor speed and direction control. There are many tutorials on the net with step by step diagrams on how to accomplish this. Hard drives disk have high speed low profile brushless motors that can be re used called bldc.

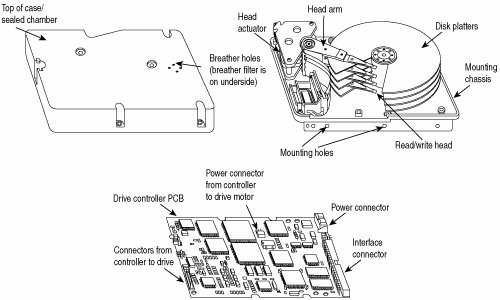

Mounting is also possible in a smaller 25 inch drive and larger 525 inch drive bay with an adapter. Unlike floppy drives where motor commands are directly send over the ide cable on hard disk drives the drives controller is expected to calculate cluster position and actuate the motor.