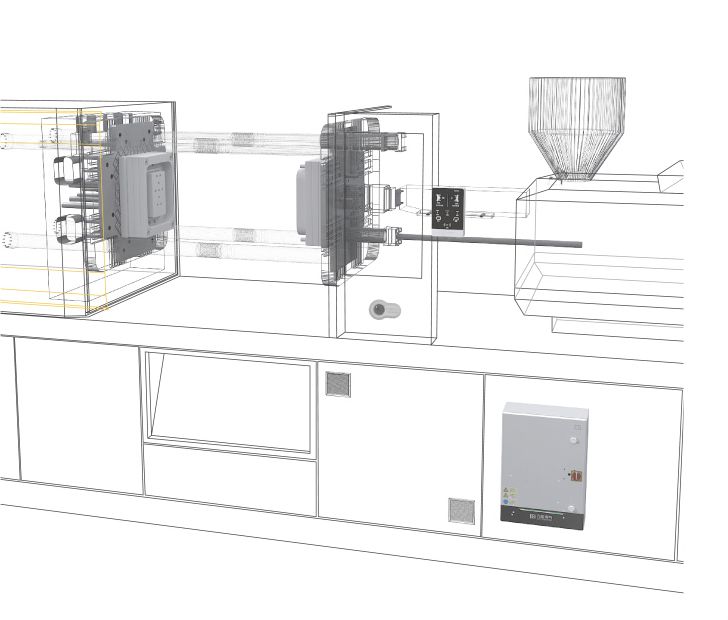

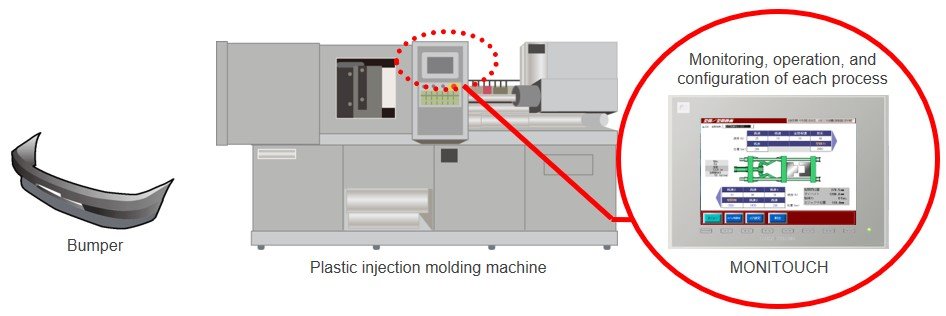

The injection moulding cycle working injection molding diagram. Below is a brief outline of the 3 lessons in this all electric injection molding machine training program.

Understanding Intensification Ratio Plastics Technology

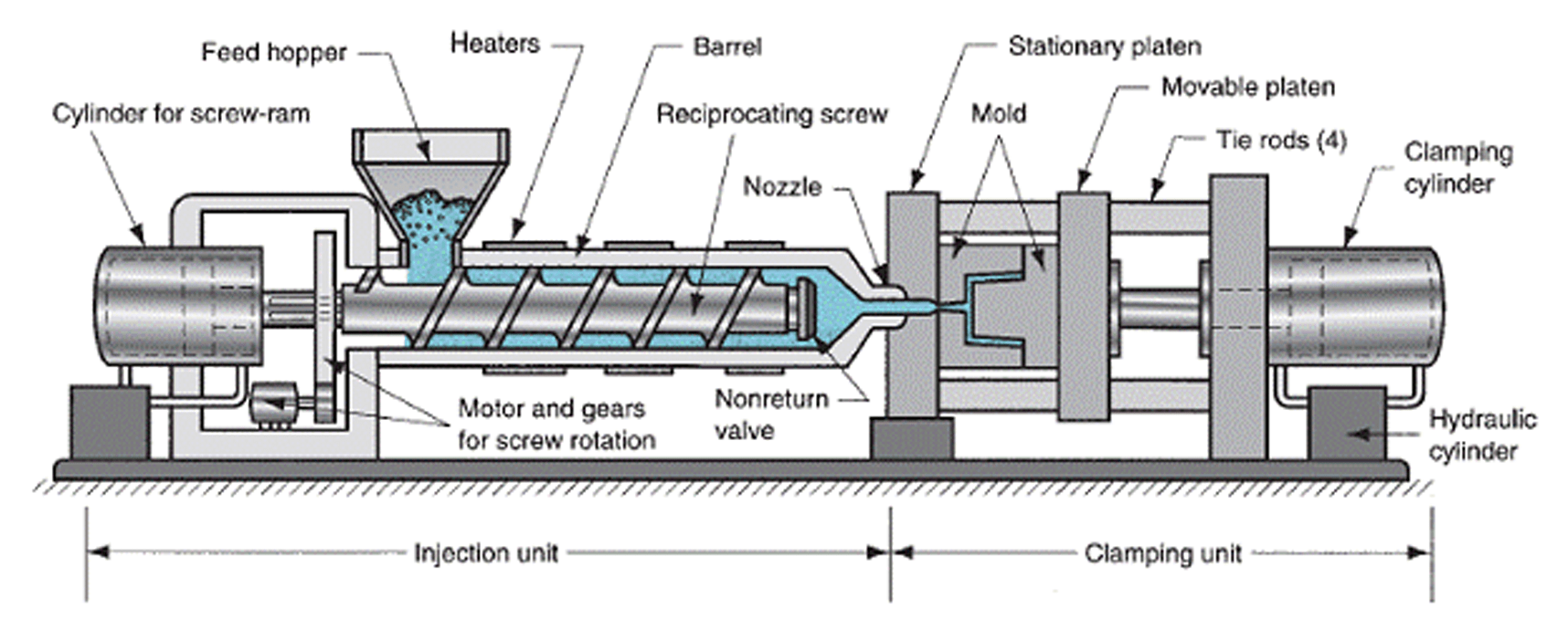

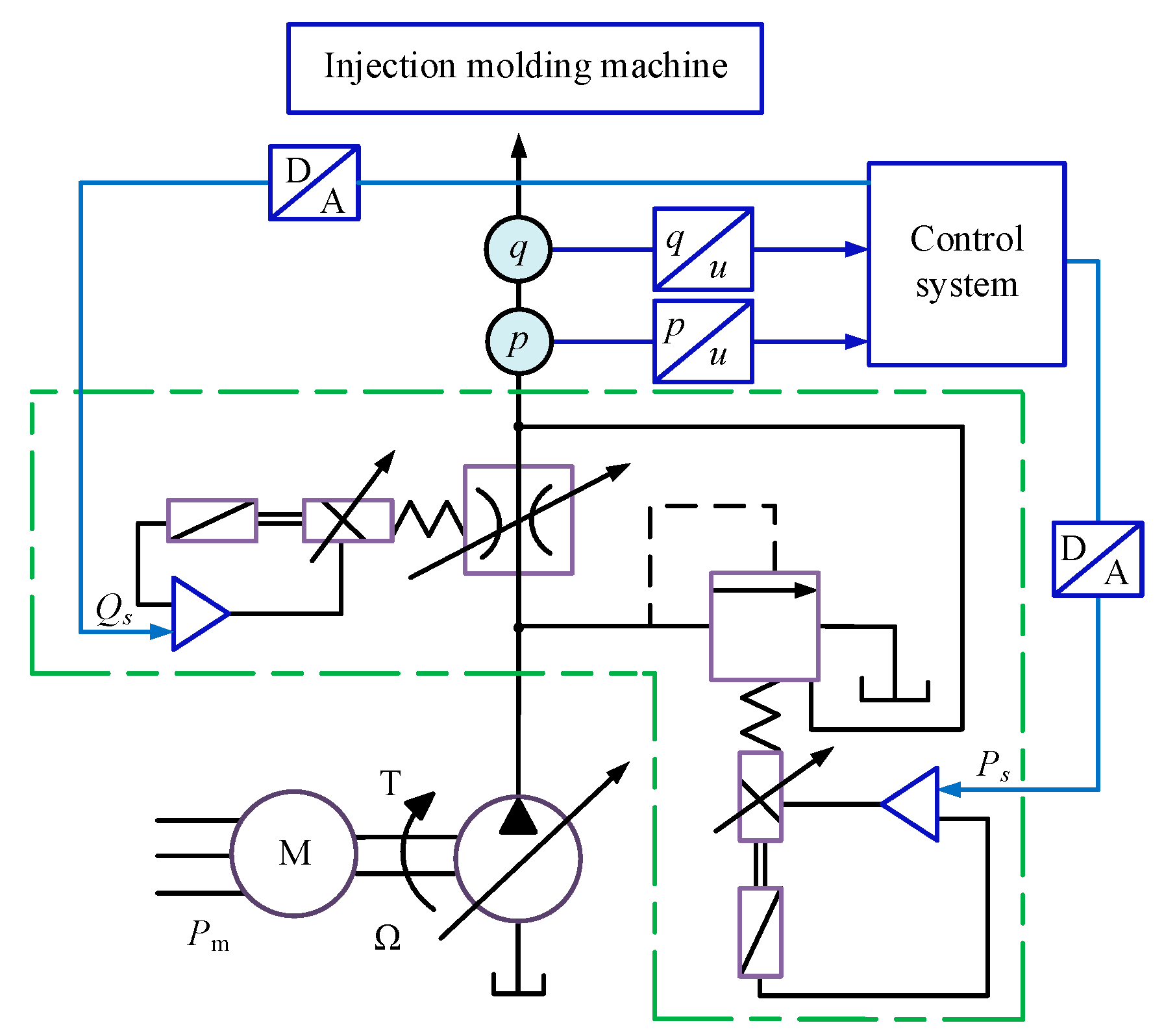

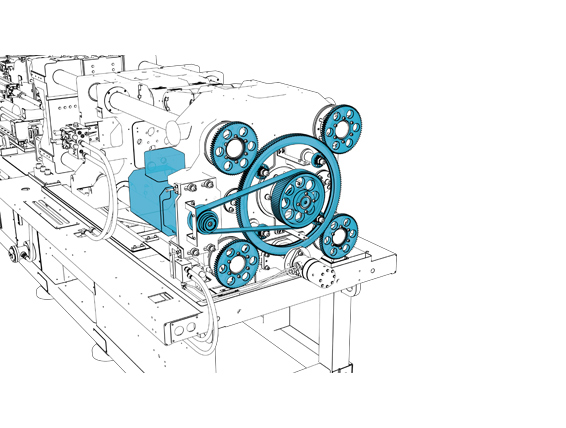

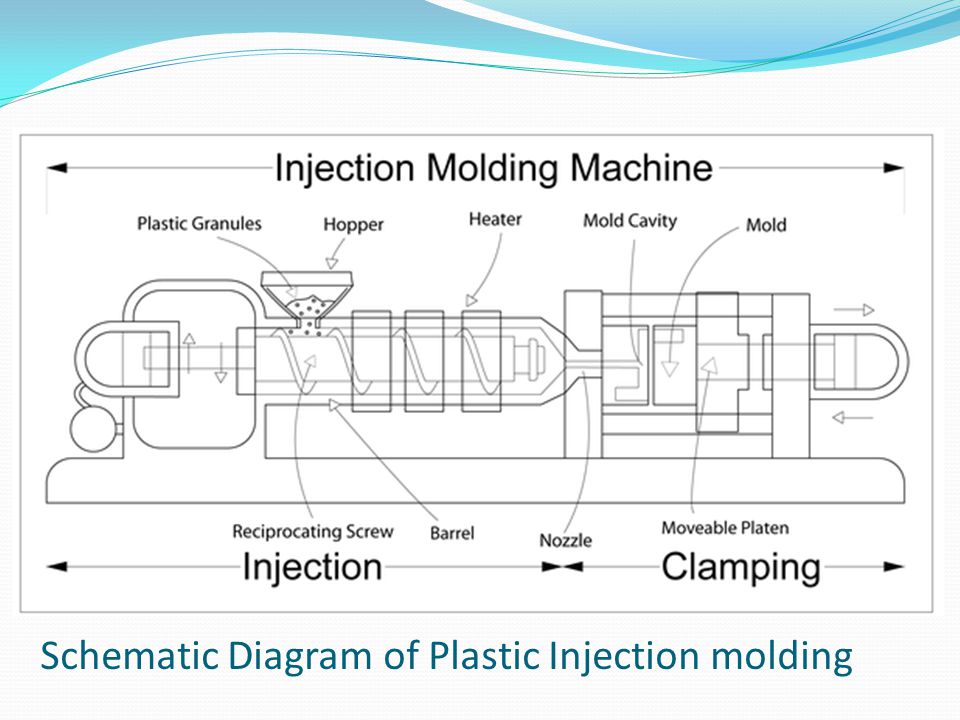

Injection molding machine electrical diagram. Hydraulic and electric with a hybrid machine available. Injection molding is a manufacturing process for producing parts by injecting molten material into a mould or moldinjection moulding can be performed with a host of materials mainly including metals for which the process is called die casting glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. Allrounder injection molding machines stand for quality reliability production efficiency and cost efficiency. They will then be able to immediately see how each control change. Lesson 1 electric machine design cycle parts the parts of the electric molding machine. The modular product range extends from the hydraulic general purpose model and hybrid high performance versions through to high precision electric and ergonomic vertical machines.

When stage 3 is completed the mould closes again. Bole injection mold machines bole injection machine bole injection mould machine bole injection molding machine bole injection moulding machine injection mold machines pet injection mould machines injection mold machine contact us tel. 2 vertical injection machine. Allrounder injection molding machines are synonymous with quality reliability and production efficiency. Stage 1 injection followed by stage 2 holding pressure and plasticating and finally stage 3 ejection of the moulded part. Our modular product range includes hydraulic hybrid electrical and vertical injection molding technology from attractive general purpose models and high precision versions to special machines for cube molds.

No99 weisan road xiaogang ningbo zhejiang. Hydraulic injection molding presses were historically the only option available until a company in japan introduced the first electric machine in 1983. However the types of presses and machines used in the injection molding process have boiled down to two. For lesson 5 employees will adjust the injection molding machine timer controls temperature controls and clamp controls. In this automatic injection blow molding machine the electrical control system consisting of world famous brand plc which is used to charge the operation of the automatic injection blow molding machine. The electrical part has complete functions such as various parameter setup panel operation display trouble alarm and temperature control etc.

There are three main stages in the injection moulding cycle.