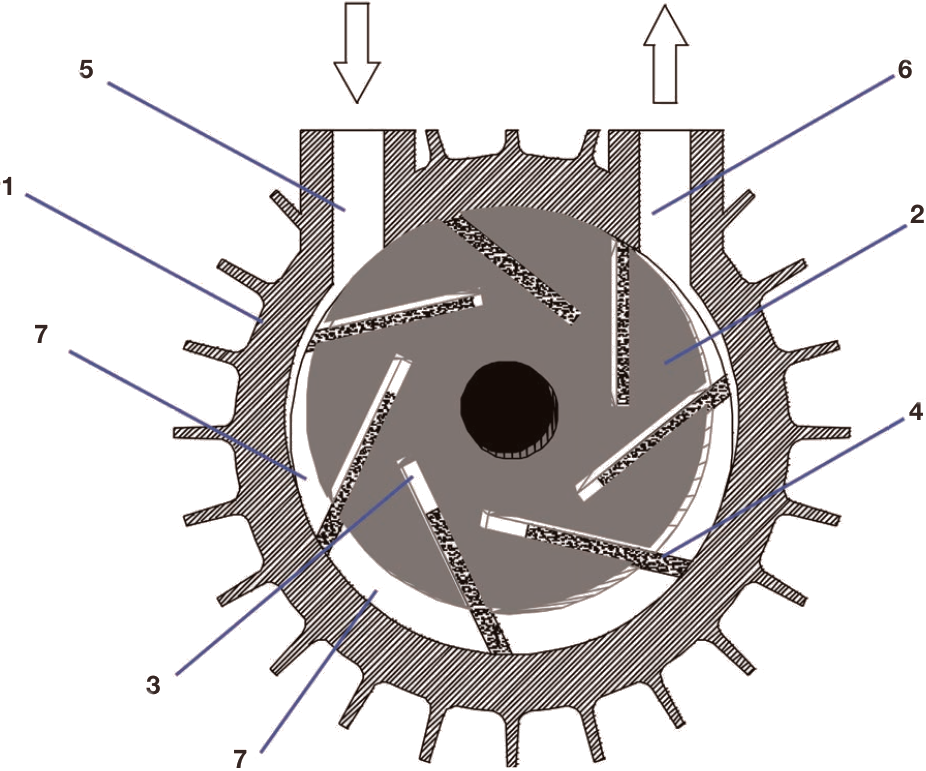

Instead of being held by two journal bearings the eccentric arm of the planetary is held by the meshing of the six tooth rotor and seven socket stator. Their vanes are self compensating for wear and vanes can be replaced easily.

Useful Information On Magnetic Drive Pumps

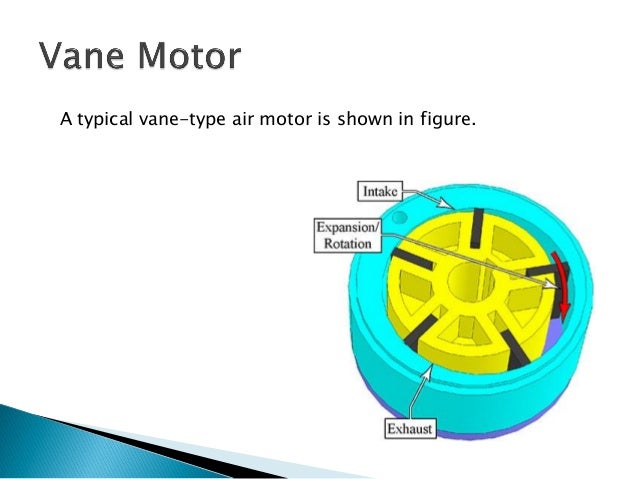

Vane motor diagram. Construction and working of balance type vane motor animation video explained with diagram balance vane motor working thanks for watching. A roller vane gerotor motor is a variation of the orbiting gerotor motor fig. Balanced vane pump diagram advantages and disadvantages of vane pumps. Vane motors work on the same principle as vane pumps in reverse. Vane motor diagram construction working application introduction. The force differential created by the unbalanced force of the pressurized fluid on the vanes causes the rotor to spin in one direction.

The advantages of vane pumps are as follows. The vanes form working chambers the volume of which increases in the turn direction. Instead of direct contact. Vane pumps are self priming robust and supply constant delivery at a given speed. A critical element in vane motor design is how the vane tips are machined at the contact. In these motors the pressurised fluid acting on the vanes cause them to rotate and thus developing the torque output.

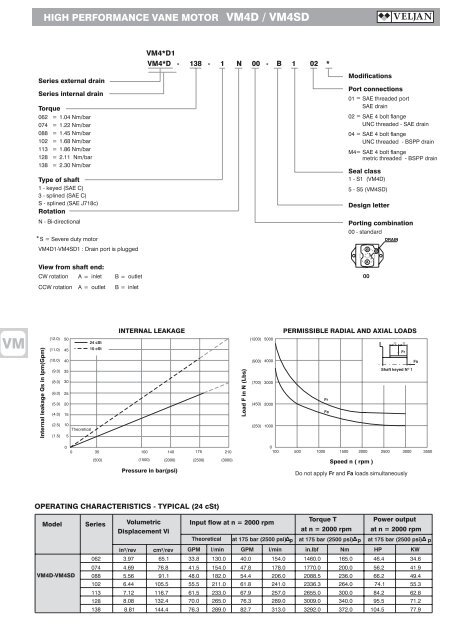

Functionality air vane motor. They provide uniform discharge with negligible pulsations. As the compressed air expands the pressure. Design and functional principle of a vanemotor vanemotors consist essentially of a rotor which revolves in an eccentrically offset perforation of the rotor cylinder. A vane motor consists of a housing with an eccentric bore in which runs a rotor with vanes in it that slide in and out. Subscribe to our youtube channel httpswww.

It has a stationary ring gear or stator and a moving planet gear or rotor.